Electrification

Accelerating the Drive to Electrification

The global auto industry is driving toward electrification and Stellantis is in full execution mode with a comprehensive electrification strategy to deliver exciting, class-leading vehicles for our iconic brands that offer advanced technology at affordable prices.

This shift is being driven, in part, by our customers with eco-consciousness being the fastest-growing trend around the world and across generations over the last 5 years. In fact, a global study shows that 64 percent of those asked consider preserving the environment as an important value.

We do, too, which is why “We Care for the Future” is one of the core values underpinning our corporate purpose: “Powered by our diversity, we lead the way the world moves.”

We are setting the course for 100% of sales in Europe and 50% of sales in the United States to be battery electric vehicles (BEVs) by the end of this decade. And we plan to offer more than 75 battery electric vehicle models and reach global annual BEV sales of 5 million units by 2030.

At Stellantis, electrification is not a one size fits all proposition. Our global engineering teams are developing vehicle platforms, propulsion and energy storage systems that will enhance the inherent DNA of each of our 14 iconic brands.

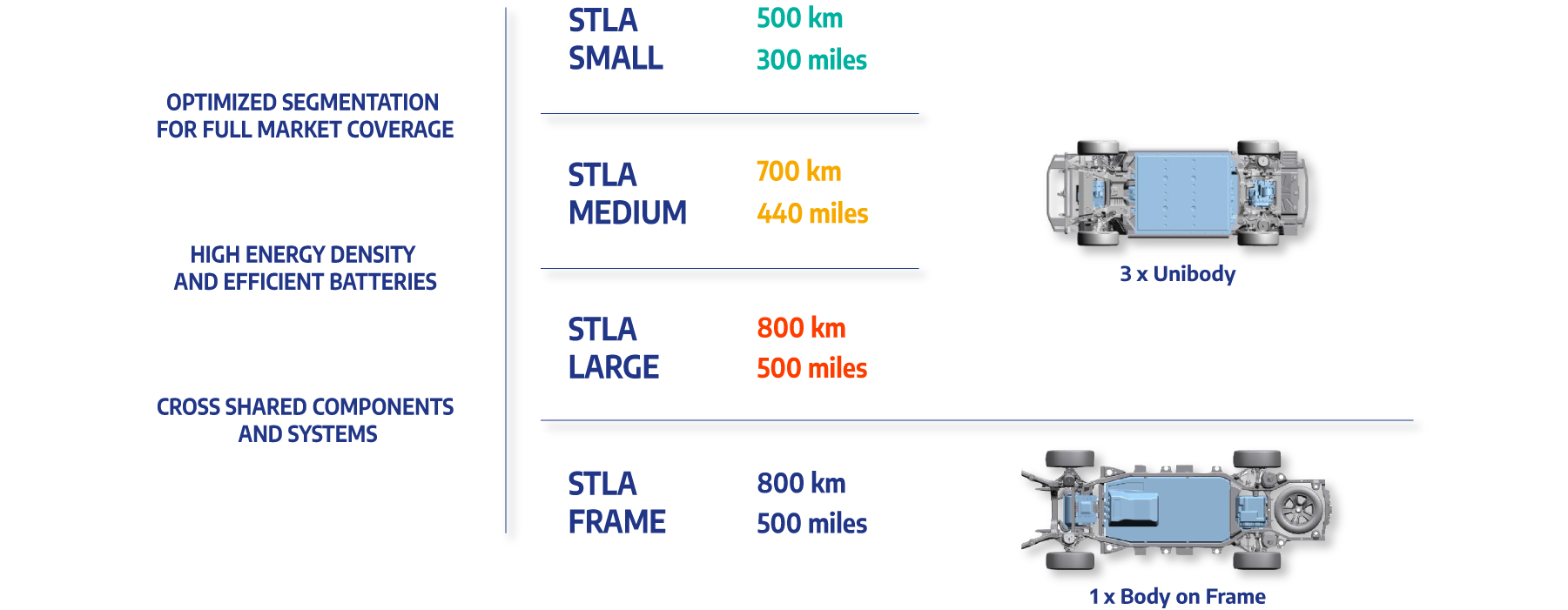

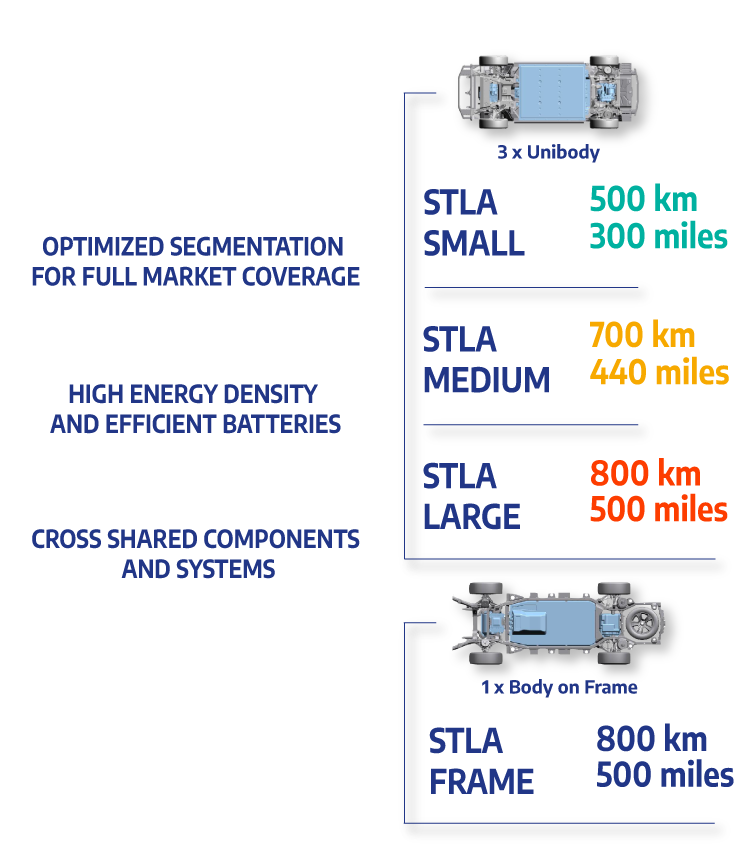

Four Global BEV-by-Design Platforms

We know that range, charging time, affordability and choice are of prime importance to our customers. Our plan calls for serving a wide variety of vehicle segments and ranges with a combination of four state-of-the-art BEV-centric vehicle platforms – STLA Small, Medium, Large and Frame – three electric drive modules (EDMs) to provide modularity and performance, and 2 battery cell chemistries to ensure affordability for all. Those combinations will offer industry-leading features, driving ranges of between 500-800 kilometers/300-500 miles and front-, rear- and all-wheel-drive propulsion.

The 4 platforms - 3 unibody and 1 body on frame - are designed with a high level of flexibility (length and width) to offer the most efficient solution for each vehicle category, from city-cars to pickup trucks and SUVs. This level of flexibility, in addition to component sharing across platforms, will reduce complexity and deliver economies of scale, with each platform capable of supporting production of up to two million units per year.

Stellantis Reveals STLA Medium Platform

STLA Medium, the first of four global BEV-by-design platforms, was unveiled in July 2023 with state-of-the-art features including best-in-class range of 700 kilometers (approx. 435 miles), energy efficiency, embedded power and charging power.

Stellantis will utilize three different EDMs that cover the full global vehicle range from the STLA Small up to the STLA Frame platform. This third-generation technology is highly flexible, with a design that is both modular and scalable (from 70kW to 330 kW), and a high level of commonality to optimize overall cost efficiency. A key element of this strategy is development of one power inverter for all three EDM families with scalable technology, common microprocessor and in-house controls and software.

By 2024, we also plan to use two battery chemistries: a nickel cobalt-free alternative which offers a low, stable cost, while at the same time optimizing density and a high energy-density option which is nickel based.

These two chemistries have a high level of synergies between them, including process and component materials and, from 2026, they will share the same cell-to-pack installation which will be upgradeable to respond to customer needs and improvements in energy density or charging speed. In addition, our first competitive solid state battery technology is targeted for introduction by 2026.

Our award-winning Jeep® vehicles with 4xe plug-in hybrid propulsion are already a hit with consumers. There will be more PHEVs from Stellantis, as they offer the capabilities of emissions-free electric propulsion combined with the extended range offered by an internal combustion engine.

We are also a leading global player in light commercial vehicles. Given the key roles these vehicles play in our communities, we’re also applying our low-emissions propulsion technologies to them, including emissions-free hydrogen fuel cell power.

Just as important, the electrified vehicles we’re developing are designed to be easily upgradeable in the future, extending their lifespans and bringing even more value to consumers. Also, we are working with partners on next-generation batteries for LEVs that will deliver greater EV range, fast recharge times of 32 km/20 miles per minute, and longer life.

Our vision is broader than just vehicles. The Stellantis electrification strategy covers a 360-degree view that includes making sure we have access to the key raw materials through to second-life use and recycling of key components such as battery packs.

With electrified products ranging from the Peugeot e-2008 to the new Fiat 500e to the Jeep family of 4xe vehicles, Stellantis is fully plugged in to the drive to sustainable, affordable mobility.

Over 800 km (500 miles) of range

Best-in-segment efficiency in energy demand for all four platforms

Best-in-class efficiency per kilometer traveled – under 12.0 kWh/100 km (U.S. market: 4.3 miles per kWh)

Acceleration from 0 to 100 km/h (0-62 mph) in as low as 2 seconds

Class-leading fast charging of 32 km (20 miles) per minute

Best-in-class energy storage efficiency with energy density reaching almost 60 kWh per meter